How Climatizer and GNI are Shaping Sustainable Building in Ontario

Sep 05, 2025

At Great Northern Insulation (GNI), our commitment to high-performance, environmentally responsible building practices is shown in both the materials we use and the manufacturing partnerships we build.

In this article, we explore our long-standing relationship with Climatizer, a leading Ontario-based manufacturer of cellulose insulation, and highlight a recent collaboration with Muskoka River Fine Homes on a high-performance cottage addition in Gravenhurst that utilized dense-pack cellulose insulation throughout the building envelope.

Locally Made, Locally Installed: Climatizer Cellulose

Climatizer has been producing cellulose insulation in Ontario since 1977, using recycled newsprint and cardboard sourced from local suppliers. The manufacturing process is straightforward: Climatizer takes a locally-sourced newsprint paper and shred s it, treats it, compresses it into bales, and finally wraps the material for delivery. The final product is an insulation material that, when fed through a hopper to “fluff” the paper back into a light, airy mixture, can be blown into an attic space, packed into a wall cavity, and more.

s it, treats it, compresses it into bales, and finally wraps the material for delivery. The final product is an insulation material that, when fed through a hopper to “fluff” the paper back into a light, airy mixture, can be blown into an attic space, packed into a wall cavity, and more.

“It’s not a complicated process, but it’s an important one,” explains Greg Love, Vice President of Sales at Climatizer. “Everything - from the paper source to the final product - is done right here in Ontario.”

This local supply chain means that GNI can deliver insulation solutions with minimal environmental impact before the product is even installed. Climatizer cellulose doesn’t travel across provinces or countries over the course of days and multiple types of transportation, it travels a short distance within Ontario from Climatizer’s facility to our warehouses and directly to job sites, keeping the carbon footprint from travel low.

What Is Cellulose Insulation?

Cellulose insulation is a plant-based, recycled material that offers excellent thermal and acoustic performance. It’s typically installed in two ways:

-

Loose-fill blown-in: Ideal for attics, this method involves fluffing the compressed cellulose and blowing it into open spaces. When Ontario homeowners think of fluffy, cloud-like attic insulation, it’s likely cellulose insulation that they’re picturing.

-

Dense-pack: Used in wall, ceiling, and floor cavities, this technique tightly packs cellulose to a specific density behind netting or membranes, ensuring complete coverage and eliminating gaps around wiring or framing. Installing cellulose in this way results in an extremely high-efficiency type of insulation that remains very environmentally friendly.

“Dense-pack cellulose fills the whole cavity,” says Greg. “It’s not like you’re going to have any gaps around electrical or anything. It densely fills your whole cavity, and it’s very soundproof and airtight.”

Fire Safety, Pest Resistance and Mold Resistance

Homeowners commonly ask Great Northern Insulation how cellulose, a paper product, can be safe to use in homes.

Climatizer’s cellulose is treated with boric acid, a naturally occurring compound that enhances fire resistance. Boric acid also prevents rodents and insects from nesting in the insulation, making it a smart choice for attics and crawl spaces.

Despite being paper-based, cellulose insulation is also resistant to mold and mildew when installed correctly. It wicks moisture into itself and distributes that water content across the material, allowing it to dry more effectively than traditional fiberglass or other insulation types.

“With the moisture-wicking properties of cellulose, it’s actually beneficial in avoiding mold,” Greg explains. “If you have too much water, of course, you’ve got bigger problems than your insulation, but cellulose gives you a better chance to dry things out.”

Builder Perspective: Blair McKenzie of Muskoka River Fine Homes

For Blair McKenzie, founder of Muskoka River Fine Homes, building sustainbly isn’t just a business decision – it's a personal mission. With over 30 years experience in the industry and a deep-rooted passion for environmentally-friendly building practices, Blair has made it his goal to bring high-performance, low-environmental impact homes to the Muskoka region.

“Being an environmentalist is just a natural state of being for me,” Blair explains. “We’re not just building homes, we’re building healthier, more durable environments for people and the planet.”

Climatizer cellulose is a perfect product for builders that are looking to incorporate environmentally-friendly building practices. Climatizer cellulose is EcoLogo certified, a mark of environmental responsibility recognized across Canada. It’s also widely used in projects aiming for LEED certification, Net Zero readiness, and Passive House standards.

“Cellulose is big in buildings that are looking to achieve LEED certification,” says Greg Love. “It’s a highly regarded material in green building circles.”

Case Study: Gravenhurst Cottage Addition

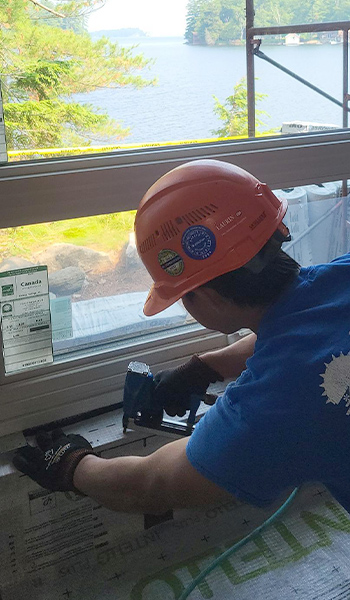

A recent collaboration between Great Northern Insulation and Muskoka River Fine Homes showcases the practical benefits of dense-pack cellulose insulation. The project involved a remote-access cottage addition in Gravenhurst, where sustainability and performance were top priorities for the cottage owner.

Blair specified dense-pack cellulose for the entire building envelope – walls, ceilings, and floors – paired with Intello membranes to create a breathable, high-performance building envelope. This approach of a building envelope created entirely out of dense-pack cellulose not only provides an extremely high R-Value (a measurement of insulation effectiveness) but also leverages cellulose’s ability to help manage moisture content, a critical feature for Ontario’s extreme climate.

“The better way to build a wall assembly is to let it breathe in both directions,” Blair explains. “In Ontario we have this crazy environment where we’ll have plus 30-degree days with 80% humidity in the summer, and the inside of the home is typically the opposite of that. If you have an air conditioner on inside the house, and it’s quite dry, that little bit of moisture will drive into the wall assembly from the outside due to the high humidity, which can lead to issues.”

Cellulose insulation is hygroscopic, meaning it will take in moisture from areas of higher levels and diffuse it to areas of lower moisture. This ability to passively regulate moisture content by diffusion helps prevent the build-up of moisture that can lead to mold and mildew growth.

“I would absolutely recommend that homebuilders and homeowners consider dense-pack cellulose on their next build,” said Blair. “Beyond just the technical benefits that I’ve mentioned, the environmental impact is so low that it can even fall on the negative side, by sequestering carbon into the material itself. In the cutting edge of natural construction, that’s the gold standard.”

“There’s no easy going back and fixing your exterior wall insulation.” He added. “You need to do all you can to squeeze performance out of your budget.”

Building Better, Together

The collaboration between Climatizer, Great Northern Insulation, and Muskoka River Fine Homes demonstrates how sustainable insulation materials and thoughtful design can come together to create homes that are not only energy-efficient, but also healthier, more durable, and better for the planet.

Whether you're a homeowner planning a retrofit or a builder designing your next high-performance project, dense-pack cellulose offers a compelling combination of thermal performance, moisture management, and environmental responsibility.

Ready to Build Better?

Contact Great Northern Insulation to learn how cellulose insulation can elevate your next project from the ground up.